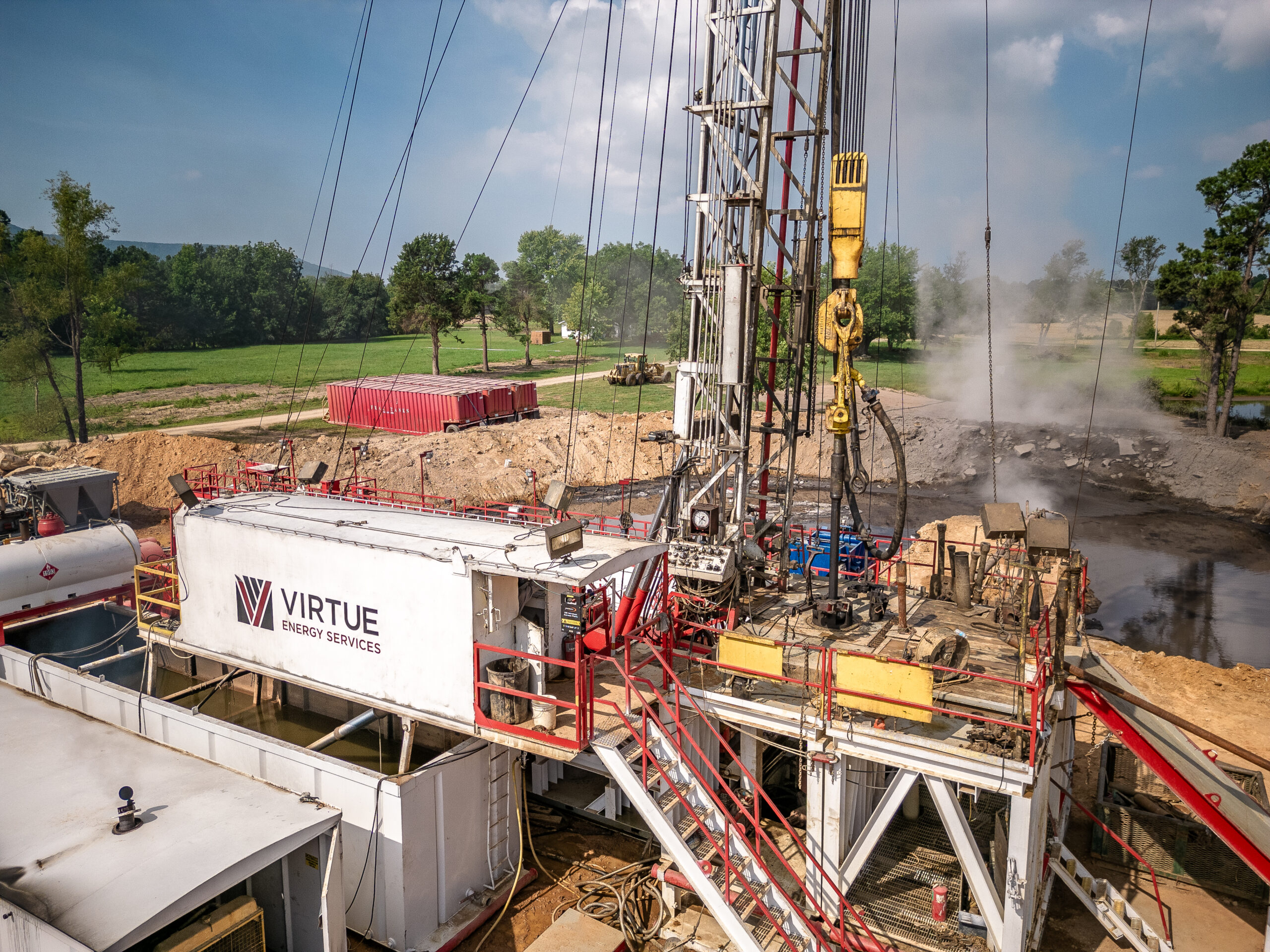

Your Trusted Partner for

Oil & Gas Drilling Services

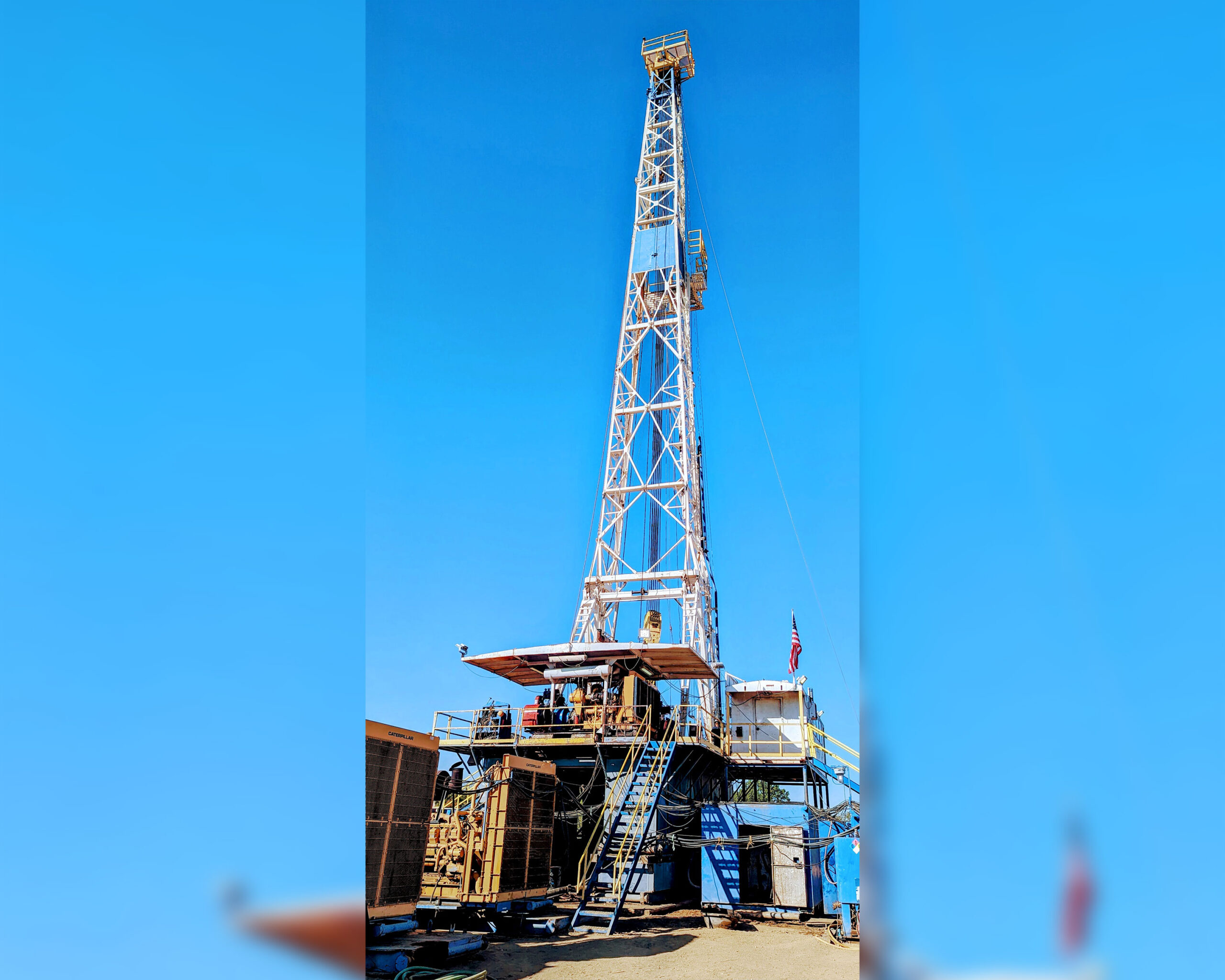

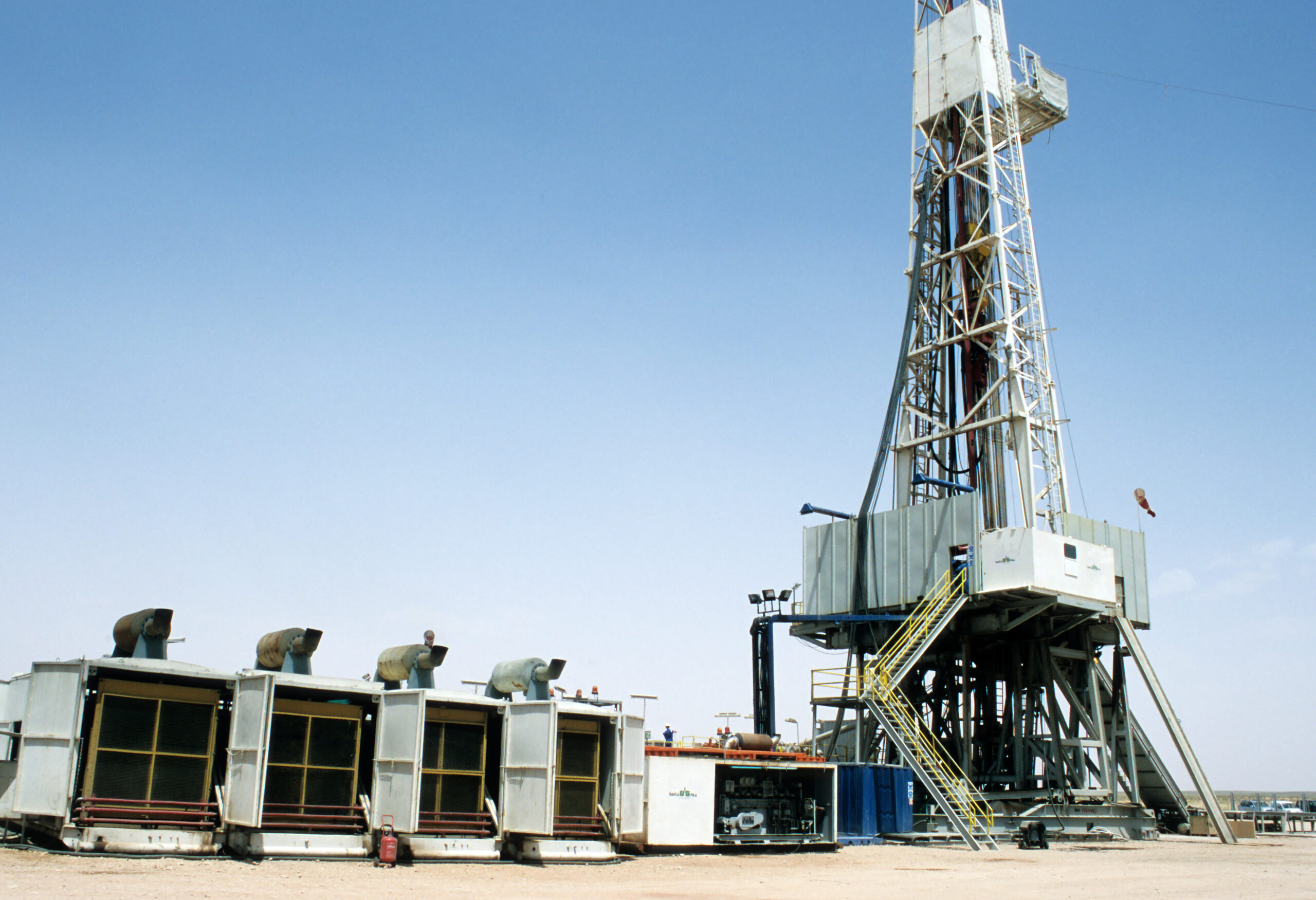

Contract

Drilling

8,000’

Taylor 750HP

PZ 205 20-½” / National 20-½” x 53-¼”

3408 CAT

112’ Telescoping Mast Rated @ 350,000 (8 line)

Dragon 12’ KB Box on Box

- Two (2) each – 315 bbl Pits

- Two (2) each – 5x6 Mud Mixing Pumps (75 HP Electric)

- Harrisburg Venturi Mud Hopper with Mixing Lines

- Vortex High Speed Shaker

- Sub Guns & Agitators

- 320 KW – 3456 CAT

- 250 KW – 3406 CAT

- Annular – 11” x 3,000 PSI Hydril

- Preventer – 11” x 3,000 PSI Shaffer Double

- Closing Unit – Air/Hydraulic with 10 HP Electric Backup and Remote Closing Station

- Choke Manifold – 4” with two (2) Manual Chokes

- **BOP’s, Closing Unit and Manifold Meet Federal Regulations**

7,500’ 16.6 PPF Grade G105 4-½” with 4-½” X-Hole Connections

- Twelve (12) – 6-¼” x 2-¼” with 4-½ X-Hole Connections

- Three (3) – 8 x 2-¼“with 6-5/8” Reg Connections

- Two (2) each – 1,150 CFM 500 PSI Sulair (C15 CAT Power)

- Two (2) each – 1,350 CFM 500 PSI Sulair (C15 CAT Power)

- One (1) Knight Booster 1200 Psi

3” Line

26

170’ x 270’

Other:

One (1) each – Independently Powered Triplex Mist Pump (CASO 3,200 Pump)

Marathon 10 HP Motor

-

- One (1) each – 500 bbl Water Tank

- One (1) each – 10,000 gal Fuel Tank

- 150 Ton Traveling Equipment (SJ Petro – Model #Y6150-4)

- 150 Ton Twister Swivel

Capacity:

13,000’

Drawworks:

Skytop Brewster N-46 900 HP Drawworks (S/N: 460040)Rotary Table:

20-1/2" National Rotary Table

(2) Allison TC-955 Torque Converters

Power:

Two (2) C-15 Caterpillar Engines (575 HP each)

Derrick:

138’ X 18-1/2’ Lee C. Moore – GNC 490,000# (S/N: T-2339)

Top Drive Compatible

Substructure:

40’L x 20’W x 14’H Box on Box Substructure

-

- One (1) 700 Bbl. Mud Tanks

- Cobra Linear Motion Shale Shaker (Dual Shaker System)

- Two (2) Centrifugal Mud Mixing Pumps

- Premix Tank

- Desander

Mud Pumps:

-

- Pump #1: - Maxum F-1600HP Triplex (S/N: 13-013) - D-3512 CAT Power (S/N: 67Z00817)

- Pump #2 - Maxum F-1600HP Triplex (S/N: 13-011) - D-3512 CAT Power (S/N: 67Z00546)

-

- 11” x 5,000# Spherical Annular BOP

- 11” x 5,000# Double Ram BOP

- 11” x 5,000# Mud Cross

- 4-1/16” x 5,000# (1) HCR and (1) Manual Choke Valves

- Two (2) 2-1/16” x 5,000# Manual Kill Valves w/Check Valve

- 4-1/16” x 2-1/16” 5,000# Choke Manifold w/Buffer Tank

- One (1) 4 Station Closing Unit w/Remote Panel

Drill Pipe:

4-½” G-105 Drill Pipe and/or 4” S-135 14.0# Ft. w/D538 Tool Joints

-

- Twenty-one (21) 6-1/8" to 6-1/2" Drill Collars

- Three (3) 8” x 6-5/8” Drill Collars

Two (2) each – Quincy 325 Compressors

Generators:

- Two (2) 300KW SR4-B Caterpillar Generators, Powered by 3406 B Caterpillar Engines

- class="p2">Curtis Toledo Screw Air Compressor

Truck Loads:

32

170’ x 270’

Other:

One (1) each – Independently Powered Triplex Mist Pump (CASO 3,200 Pump)

Marathon 10 HP Motor

-

- One (1) – 500 bbl Water Tank

- One (1) – 9,400 gal Fuel Tank

- 300 Ton Swivel

- Satellite Automatic Driller

- Vapor Proof Lighting System

- 3” Air Cooler Line

Completion

Work

Workover

Plug & Abandonment

Specs:

-

- Service King SK 475 Workover Rig

- Service Depth: 10,000’ 2 7/8” Tubing

- Draw Works: SK 42” X 10” DD lebus grooved 1” Main Drum / 12,500’ of 9 1/16” sand line Both Drums are splash water cooled, Main Drum w/ Regulated Disc Assist

- Engine: Detroit Series 60 12.7L (475 HP)

- Transmission: Allison 755, 5 speed

- Derrick: 96’ x 240,000lbs Mast

- Tubing Board Capacity – Double stands, 14,500’ – 2 7/8” Tubing

- Rod Basket Capacity – 75’ Triple Stands – 12,000’ – 7/8” Sucker Rods

- Traveling Block: Mckissick 83A 100 ton 3 sheave grooved for 1”

- Base Beam: 5’ X 41’ Concrete filled across leg pad with Guy wire tie down

Workover rig comes with 4.5” tubing tongs, Guiberson T-60 Slips, Rod tools for 5/8” – 7/8” Sucker rods, Swab lubricator with standard swab tools, Base Beam, Crew truck and Dog house.

Specs:

-

- Franks 500 w/ NOV Mast Workover Rig

- Service Depth: 14,500’ 2 7/8” Tubing

- Draw Works: Franks 1287 DD 1” 6 lines/ 12,500’ of 9 1/16” sand line Both Drums are splash water cooled / Regulated Disc assist

- Engine: Detroit Series 60 12.7L (475 HP)

- Transmission: Allison 5960 6 speed

- Derrick: 104’ x 250,000lbs Mast

- Tubing Board Capacity – Double stands, 14,500’ – 2 7/8” Tubing

- Rod Basket Capacity – 75’ Triple Stands – 12,000’ – 7/8” Sucker Rods

- Traveling Block: Mckissick 73-A 100 ton Spring Loaded 3 sheave grooved for 1”

- Base Beam: 5’ X 41’ Concrete filled across leg pad with Guy wire tie down

Workover rig comes with 4.5” tubing tongs, Guiberson T-60 Slips, Rod tools for 5/8” – 7/8” Sucker rods, Swab lubricator with standard swab tools, Base Beam, Crew truck and Dog house.

Specs:

-

- Franks 500 Workover Rig

- Service Depth: 14,500’ 2 7/8” Tubing

- Draw Works: Franks 1287 DD 1” 6 lines/ 14,000’ of 9 1/16” sand line Both Drums are splash water cooled with Parmac Hydromatic assist

- Engine: Detroit Series 60 12.7L (475 HP)

- Transmission: Allison 5960 6 speed

- Derrick: 104’ x 250,000lbs Mast

- Tubing Board Capacity – Double stands, 14,500’ – 2 7/8” Tubing

- Rod Basket Capacity – 75’ Triple Stands – 12,000’ – 7/8” Sucker Rods

- Traveling Block: Mckissick 83A 100 ton 3 sheave grooved for 1”

- Base Beam: 5’ X 41’ Concrete filled across leg pad with Guy wire tie down

Workover rig comes with 4.5” tubing tongs, Guiberson T-60 Slips, Rod tools for 5/8” – 7/8” Sucker rods, Swab lubricator with standard swab tools, Base Beam, Crew truck and Dog house.

Specs:

-

- Franks 300 Tri-Scope Workover Rig

- Service Depth: 8,000’ 2 7/8” Tubing

- Draw Works: Franks 658 DD 7/8” 4 lines/ 8,000’ of 9 1/16” sand line Both Drums are splash water cooled

- Engine: Detroit Series 60 12.7L (400 HP)

- Transmission: Allison 4460 5 speed

- Derrick: 96’ x 120,000lbs Mast

- Tubing Board Capacity – Double stands, 8,000’ – 2 7/8” Tubing

- Rod Basket Capacity – 75’ Triple Stands – 8,000’ – 7/8” Sucker Rods

- Traveling Block: Mckissick 20” 82A 50 ton 3 sheave grooved for 7/8”

- Base Beam: 5’ X 41’ Concrete filled across leg pad with Guy wire tie down

Workover rig comes with 4.5” tubing tongs, Guiberson T-60 Slips, Rod tools for 5/8” – 7/8” Sucker rods, Swab lubricator with standard swab tools, Base Beam, Crew truck and Dog house.

Specs:

-

- Sky Top RR 400 Workover Rig

- Service Depth: 10,000’ 2 7/8” Tubing

- Draw Works: RR 418 DD lebus grooved 1” Main Drum / 12,500’ of 9 1/16” sand line Both Drums are splash water cooled, Main Drum w/ Regulated Disc Assist

- Engine: Detroit Series 60 12.7L (475 HP)

- Transmission: Allison CLBT 4460-2, 5 speed

- Derrick: 95’ x 180,000lbs Mast

- Tubing Board Capacity – Double stands, 14,500’ – 2 7/8” Tubing

- Rod Basket Capacity – 75’ Triple Stands – 12,000’ – 7/8” Sucker Rods

- Traveling Block: Mckissick 83A 100 ton 3 sheave grooved for 1”

- Base Beam: 5’ X 41’ Concrete filled across leg pad with Guy wire tie down

Workover rig comes with 4.5” tubing tongs, Guiberson T-60 Slips, Rod tools for 5/8” – 7/8” Sucker rods, Swab lubricator with standard swab tools, Base Beam, Crew truck and Dog house.

Specs:

- Wilson Mogul 42, 300 series Work Over Rig

- Service Depth: 10,000’ 2 7/8” Tubing

- Draw Works: Wilson 42 DD lebus grooved 1” Main Drum / 12,500’ of 9 1/16” sand line Both Drums are splash water cooled, Main Drum w/ Regulated Disc Assist

- Engine: Detroit Series 60 12.7L (475 HP)

- Transmission: Allison 5860, 5 speed

- Derrick: 96’x180,000lbs Mast

- Tubing Board Capacity–Double stands, 14,500’–2 7/8”Tubing

- Rod Basket Capacity–75’TripleStands–12,000’–7/8”Sucker Rods

- Traveling Block: Mckissick 83A 100 ton 3 sheave grooved for 1”

- Base Beam: 5’X41’ Concrete filled across leg pad with Guy wire tie down

Workover rig comes with4.5”tubing tongs, Guiberson T-60 Slips, Rod tools for 5/8”–7/8” Sucker rods, Swab lubricator with standard swab tools, Base Beam, Crew truck and Dog house.

Snubbing

Applications:

-

- Running or pulling production tubing

- Frac plug drillout

- Running or pulling packers, bridge plugs, gas lifts mandrels

- Fishing operations

- Underbalanced completions and drillouts

- Pulling or landing isolations hangers

- Plug & Abandonment (P&A) operations

Specifications:

-

- 5000psi - 7-1/16" snubbing stack bore

- 6' jack stroke

- 1, 7-1/16" single ram integrated IE BOP

- 5000psi Shaffer type annular

- Handles tubulars up to 3-1/2" at max 1500psi

- 2-7/8" and smaller tubing 2200psi

- Full open Oil Country style slips

- Pipe handling winch with safety elevator for lifting and laying down tubing

Our experienced team and leadership will provide the expertise and attention needed to get the job done right.